U1, 179 Gympie Terrace, Noosaville, QLD, Australia 4566

[email protected]

call now +617 5455 6297

Decoration Styles

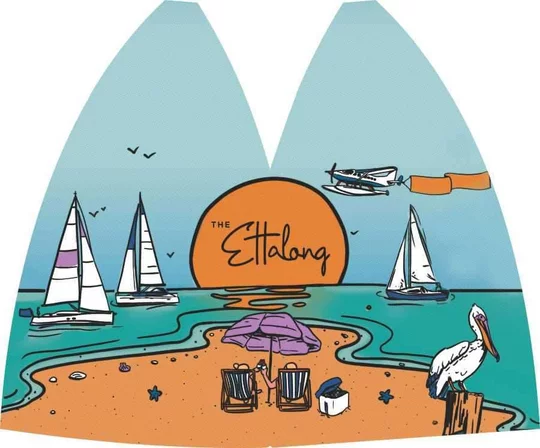

Sublimated Print

Sublimated print can be used as a full cover print on the front crown, on top of the brim or under the brim. The best fabrics to print are microfibre or knit/foam surfaces. Sublimation is not recommended for cotton or acrylic surfaces because the twill weave in those fabrics could cause irregularities. You can use other decoration styles over the top of a sublimated print. Yes we can print on the mesh/per/panel.

Flat Embroidery

Flat embroidery is the most common decoration used as it can be applied to any surface of the item. When using in text ensure the minimum text size must be at least 6mm high to be legible and if using outlines must be at least 2-3mm wide or end-on-end stitching may result. A mixture of flat and 3D embroidery can be used in the same logo.

3D Embroidery

3D embroidery allows us to give the decoration that “kick” from the fabric surface and emphasize the stand-out of the logo. Text or logo must be at least 15mm high to use 3D embroidery. A mixture of flat and 3D embroidery can be used in the same logo. 3D embroidery is great for a clean and clear message, not recommended for complicated and detailed logos. Some fonts cannot be used for 3D due to the thin areas of the font.

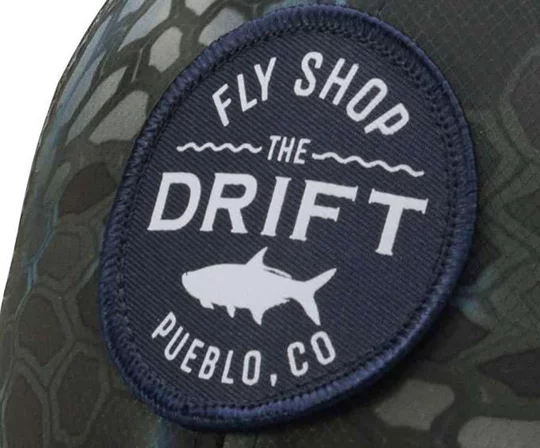

Embroidered Badge

Embroidered patch sewn on with merrow edging. As it is embroidered text must be at least 5-6mm high. The design is limited to square, oblong and round shapes. Merrow edging is like a bulk border around the patch and can have a dynamic lift to emphasize the logo/artwork. Merrow edging is usually 3-4mm wide.

Embroidered Badge

Smooth Edge

Embroidered badge sewn on with smooth edging. As it is embroidered, text must be at least 5-6mm high. The design is limited to square, oblong and round shapes. Smooth edging is like a silk finish border around the patch and can have a continue flow to the finished item.

Embroidered Badge

Distressed Edge

Embroidered badge sewn on with distressed or frayed edging. As it is embroidered, text must be at least 5-6mm high. The design is limited to square, oblong and round shapes. The distressed badge edge is ideal for beach, tropical and grunge finish items.

Woven Badge

The advantage of a woven badge is that you can fit in a lot more detail as they use a finer thread and it’s woven into the fabric. This also allows finder and smaller text size with sharper definition. With the woven badge you can also use gradient artwork like sunsets and logo work.

Screen Printed Badge

Merrow or Smooth Edge

With a screen print badge you can add smaller text within the logo which can be a great advantage when you have detailed objects to show and a range of lines and text.

PU Leather Badge

Direct Sew-On

Direct sew-on PU leather look badge in de-bossed format. Normally one or two colour design is effective. The advantage of this option is there are hundreds of colours in the PU leather from leather looks to nice bright contrast leathers.

3D Plasti-Weld

Heat Pressed On

3D plasti-weld is the third most common decoration we use. The benefit of using this method is that it enables the client to use small text and features to enhance the decoration in 3D. It is made through a series of plugs injected plastics and heat sealed on the fabric surface. Can be used on any flat surface of the item.

Leather Badge

Embossed or De-Bossed

The leather badge decoration can offer an authentic alternative to show off your logo. The man made leather look offers text/logos in de-bossed or embossed alternatives, great in a rural setting.

Rubber Badge

Embossed or De-Bossed

The rubber badge is a great 3D alternative in decoration options to use to highlight your message and make your item really classy. The rubber badge is a little more expensive than normal as a plug and die needs to be made to allow the rubber to be poured into the mould, but can have great effects. Commonly added as a decoration around the rear mesh closure.